Recently, the team led by academician Wang Shuangfei in college of light industry and food engineering of Guangxi University has gained new progress in research for cellulosic triboelectric materials. Based on excellent biodegradability and triboeletric characteristic of cellulose, this research has resolved the problem of easy peeling and fragmentation of the interface between polymer substrate and conductive coating in green flexible electronic products by meas of dynamic covalent chemistry, which has provided an idea to reduce pollution of petroleum-based electronic waste. Titled “A Tough Monolithic Integrated Triboelectric Bioplastic Enabled by Dynamic Covalent Chemistry”, the related research results were published on Advanced Materials (the top international academic journals in the field of materials). In this paper, the first author is Shao Yuzheng, a master’s degree student of the College of Light Industry and Food Engineering, and the corresponding author is Nie Shuangxi, the professor of the College of Light Industry and Food Engineering. Guangxi University is the sole completion unit of the paper.

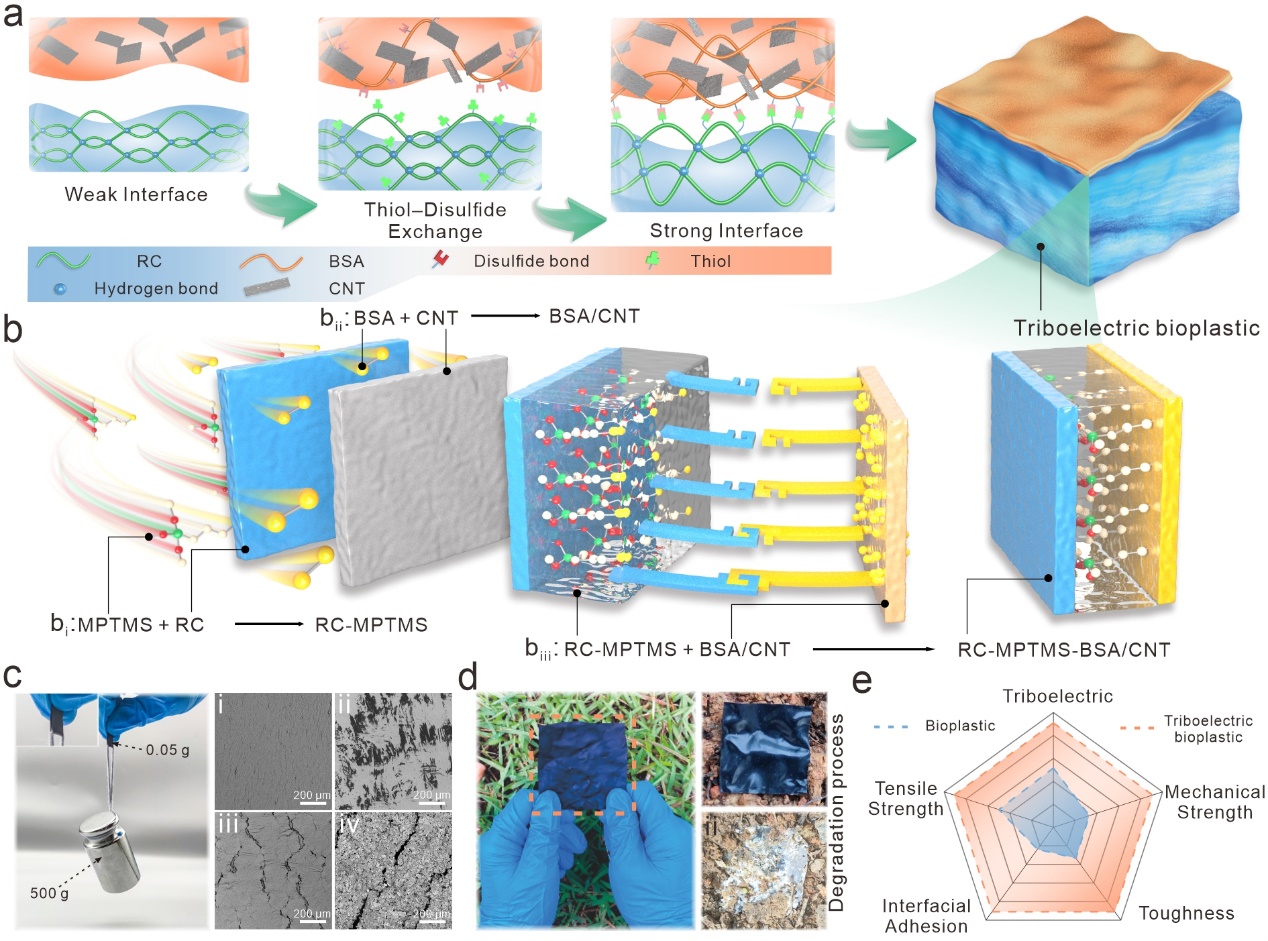

The growing threat of electronic waste to global environment and human health is of particular concern.Cellulose-based green electronics are ideal alternatives to petroleum-based electronics. However, the weak adhesive interface with mechanical mismatch in practical applications will seriously affect the electron transfer efficiency of flexible cellulose friction electric materials and lead to the failure of sensor devices. To address this challenge, academician Wang Shuangfei's team prepared a degradable monolithic integrated friction electric bioplastic using a dynamic covalent chemistry-induced interfacial interlocking strategy that utilizes the chemoselectivity and site-specificity of the thiol-disulfide bond exchange reaction. Stress is dissipated through dynamic covalent bonding adapted to interfacial interactions, enabling effective interfacial adhesion between the dielectric and conductive layers in green electronics. This monolithic integrated friction electric bioplastic allows stable operation without additional electrode patches and exhibits good mechanical properties in complex environments compared to conventional electronic materials.

This achievement is another major breakthrough for the "Advanced Lignofiber Materials" group of Academician Wang Shuangfei's team, following the publication of cellulose friction electric materials research results in Nature Communications, Advanced Materials and other international journals of great influence in 2022, which reflects the team's steady advancement in the construction of basic scientific research team and the quality of postgraduate training initiatives in recent years.

The "Advanced Wood Fiber Materials" group is committed to the development of biomass functional materials and advanced application research, pioneered and led the development of cellulose friction electric materials, systematically researched the basis of the molecular design of cellulose friction electric materials, formed a complete theoretical system of cellulose friction electric performance regulation, and built a series of high-performance cellulose friction electric materials. Series of basic research to solve the cellulose structure and friction electrical properties of the relationship between the key scientific issues are not clear, to achieve the functionalization of natural cellulose applications, for the sustainable development of China's paper industry to provide a strong scientific support.